|

Item |

Details |

|

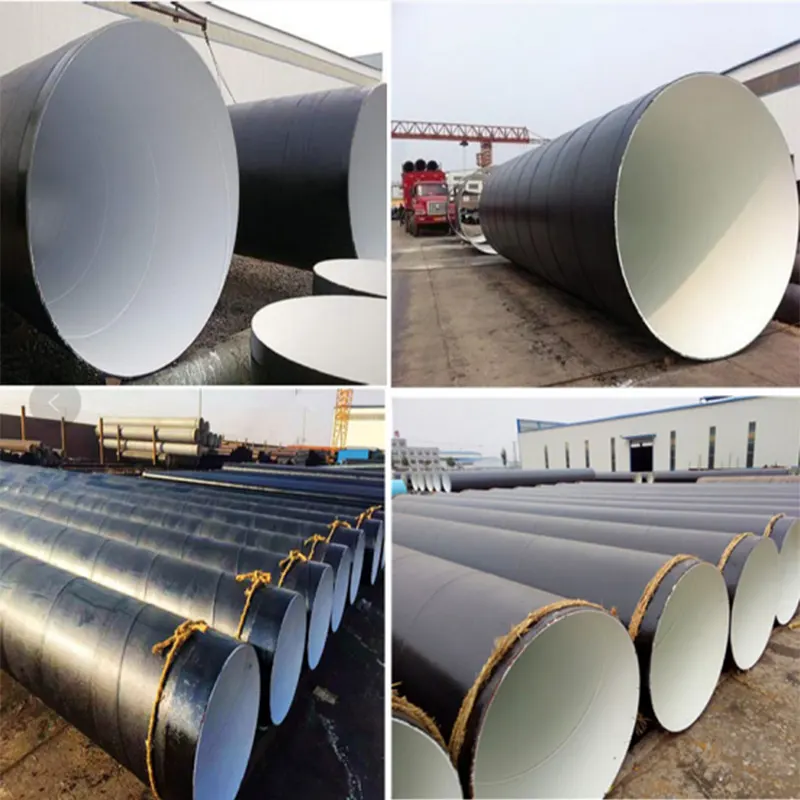

Product Name |

Water Well Casing Pipe |

|

Key Identifiers |

Construction welded pipe, welded structural water pipe, API 5L well casing |

|

Diameter (OD) |

4" to 24" (DN100 to DN600) – compatible with large diameter water pipeline projects |

|

Wall Thickness (WT) |

3mm to 12mm |

|

Length |

6m to 12m; custom lengths and threading available |

|

Material Grades |

- Carbon Steel: API 5L Gr. B, ASTM A53 Gr. A/B, ASTM A500 Gr. B- Corrosion/Low-Temperature Resistant: ASTM A333 Gr. 1/Gr. 6, ASTM A589- Coated Options: Galvanized, epoxy-lined, polyethylene-wrapped |

|

Welding Technology |

Electric Resistance Welding (ERW), Submerged Arc Welding (SAW) |

|

Key Mechanical Properties |

- Yield Strength: 235MPa (ASTM A53 Gr. A) to 355MPa (API 5L Gr. B)- Tensile Strength: 330MPa (ASTM A53 Gr. A) to 490MPa (API 5L Gr. B)- Corrosion Resistance: Enhanced by coatings for saline/acidic groundwater |

1. Raw Material Preparation:

Selection of high-quality steel coils/strips (carbon/corrosion-resistant) to meet Construction welded pipe and water well standards.

2. Forming:

Precision roll-forming into cylindrical shape, ensuring dimensional accuracy for well installation and large diameter water pipeline compatibility.

3. Welding:

ERW or SAW techniques to create leak-proof seams—critical for maintaining well integrity and preventing groundwater contamination.

4. Sizing & Straightening:

Calibration for roundness and straightness, enabling smooth driving into diverse soil conditions across target regions.

5. Surface Treatment:

Application of galvanized, epoxy-lined, or polyethylene-wrapped coatings to resist corrosion from saline/acidic groundwater and harsh climates.

6. Threading (Optional):

Custom threading for secure joint connections in deep well projects.

7. Quality Testing:

Hydrostatic pressure testing, ultrasonic (UT) inspection, and corrosion resistance testing to comply with API 5L and ASTM standards.

8. Packaging:

Preparation for regional shipping with moisture-proof protection.

Superior Corrosion Resistance:

Coated variants (galvanized/epoxy-lined) and corrosion-resistant grades withstand saline groundwater, tropical humidity, and arid soil erosion.

Pressure & Load Bearing:

Engineered to handle subsurface pressures and installation forces, ensuring well stability in diverse geological conditions.

Safe Water Conveyance:

Leak-proof welded seams prevent groundwater contamination, meeting potable water standards (NSF/ANSI 61).

Versatile Applications:

Suitable for potable water wells, irrigation, geothermal systems, and dewatering—aligning with regional water needs.

Large Diameter Compatibility:

4"-24" range integrates with large diameter water pipeline projects for municipal/industrial water supply.

Cost-Effective & Durable:

As a construction steel pipe supplier, we offer long-lasting casing pipes that reduce maintenance and replacement costs.

Our Water Well Casing Pipe complies with global and regional water infrastructure standards:

|

Application |

Recommended Grade |

Key Specifications |

Target Region |

|

Potable Water Wells |

API 5L Gr. B, Epoxy-Lined |

OD 6"-12", WT 4-8mm, NSF/ANSI 61 compliant |

All Regions |

|

Agricultural Irrigation Wells |

ASTM A53 Gr. B, Galvanized |

OD 8"-24", WT 5-10mm, large diameter water pipeline compatible |

Africa, Southeast Asia |

|

Geothermal Wells |

ASTM A333 Gr. 6 |

OD 4"-10", WT 6-12mm, low-temperature resistance |

West Asia, Middle East |

|

Municipal Water Supply Wells |

API 5L X42, Polyethylene-Wrapped |

OD 12"-24", WT 8-12mm, corrosion-resistant |

All Regions |

|

Dewatering/Construction Wells |

ASTM A500 Gr. B |

OD 6"-16", WT 4-8mm, durable for temporary/permanent use |

Africa, Southeast Asia |

|

Region |

Mandatory Documents |

Our Support (as construction steel pipe supplier) |

|

Middle East (GCC) |

SASO Certificate, API 5L Certificate, NSF/ANSI 61 Compliance |

Assist with SASO application (3-5 working days) |

|

West Asia (Iran/Iraq) |

ISIRI Certificate, Bilingual Test Reports, Import License |

Provide Persian/English documents for clearance |

|

Africa (Nigeria/Kenya) |

SONCAP Certificate, Form M (Nigeria), Potable Water Compliance Letter |

Support SONCAP registration and product testing |

|

Southeast Asia (Indonesia/Thailand) |

SNI/TIS Certificate, Customs Declaration, Corrosion Test Reports |

Coordinate with local agents for smooth clearance |

RFQ Question: Do your water well casing pipes resist saline groundwater in coastal regions?

Answer: Yes, our epoxy-lined/galvanized API 5L Gr. B pipes offer superior saline corrosion resistance.

RFQ Question: Need large diameter (20"+) casing pipes for municipal water supply wells—are they compatible with water pipelines?

Answer: Our ASTM A53 Gr. B large diameter casing pipes (20"-24") integrate seamlessly with large diameter water pipeline systems. They’re corrosion-resistant, meet AWWA C200 standards.

RFQ Question: Are your casing pipes suitable for geothermal wells in temperature-fluctuating regions?

Answer: Yes, our ASTM A333 Gr. 6 low-temperature steel pipes withstand -45°C to 120°C fluctuations. They’re ideal for geothermal systems, meet API Q1 standards with technical support.

RFQ Question: Can you supply corrosion-resistant pipes for irrigation wells in arid, sandy soils?

Answer: Our galvanized ASTM A500 Gr. B pipes resist arid soil erosion and groundwater salinity. They’re durable for agricultural irrigation.

RFQ Question: What grade of casing pipe is best for potable water wells in tropical wet regions?

Answer: We recommend API 5L Gr. B with epoxy lining—resists tropical humidity and bacterial corrosion. It meets potable water safety standards, delivers in 15-20 working days, and includes corrosion test reports.

RFQ Question: Do your pipes support threading for deep well splicing (over 12m)?

Answer: Yes, our pipes are available with custom threading for secure deep well splicing. We use API 5L Gr. B for consistency, provide threading guidelines.