|

Item |

Details |

|

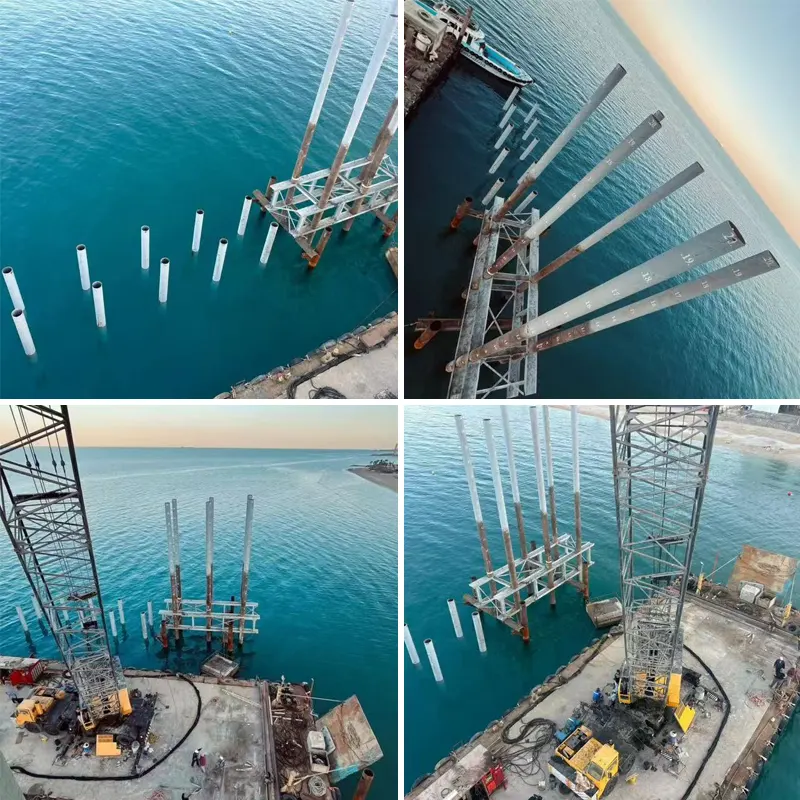

Product Name |

Bridge Construction Steel Tubes |

|

Profiles |

Round, square, rectangular |

|

Core Dimensions |

- Diameter/Width: Up to 1,200mm- Wall Thickness: 6mm to 50mm- Length: Standard 6m-18m; custom lengths available up to 24m |

|

Material Grades |

- High-Strength Low-Alloy (HSLA): ASTM A572 Gr. 50, A992- Weathering Steel: ASTM A588, A709 Gr. 50W- Carbon Steel: ASTM A36, A529- High-Yield Steel: ASTM A514, A517 (for critical load-bearing parts)- Bridge-Specific: EN 10025-4 S355/S460, JIS G3106 SM490/SM570 |

|

Welding Technology |

Submerged Arc Welding (SAW), Electric Resistance Welding (ERW) |

|

Key Mechanical Properties |

- Yield Strength: 235MPa (ASTM A36) to 690MPa (ASTM A514)- Tensile Strength: 400MPa (ASTM A36) to 827MPa (ASTM A514)- Impact Resistance: Compliant with Charpy V-notch testing for low-temperature regions |

1. Raw Material Preparation:

Selection of high-grade steel coils/plates per bridge-specific standards to ensure strength and corrosion resistance.

2. Forming: Precision

roll-forming or press-bending into round, square, or rectangular profiles using advanced equipment.

3. Welding:

Submerged Arc Welding (SAW) for thick-wall tubes or Electric Resistance Welding (ERW) for high-precision seams—ensuring structural integrity.

4. Sizing & Straightening:

Calibration to tight dimensional tolerances for roundness, straightness, and width consistency, enabling seamless assembly.

5. Heat Treatment:

Normalizing, quenching, and tempering to enhance mechanical properties—critical for high-yield steel tubes.

6. Surface Treatment:

Shot blasting, priming, and painting (or weathering steel finishing) to resist humidity, salt spray, and desert erosion.

7. Testing & Inspection:

Dimensional checks, ultrasonic testing (UT), magnetic particle inspection (MPI), weld quality verification, and impact testing.

8. Finishing:

Cutting to standard or custom lengths, with end beveling for easy on-site welding and integration.

Exceptional Load-Bearing Capacity:

High-strength steel grades support heavy highway/railway loads and long-span bridge designs.

Corrosion & Climate Resistance:

Weathering steel variants (ASTM A588/A709 Gr. 50W) develop a protective patina, while coated options withstand coastal salt spray and tropical humidity.

Structural Stability:

Rigorous welding and heat treatment ensure resistance to dynamic stresses (traffic, wind, seismic activity).

Versatile Profiles:

Round, square, and rectangular tubes adapt to diverse bridge components (piers, bracing, trusses).

Easy Fabrication & Installation:

Precision dimensions enable seamless welding and assembly, reducing on-site construction complexity.

Long-Term Durability:

Low-maintenance design minimizes upkeep costs, ideal for remote bridge projects across target regions.

Our Bridge Construction Steel Tubes comply with global and regional infrastructure standards:

|

Application |

Recommended Material Grade |

Key Specifications |

Target Region |

|

Bridge Piers/Abutments |

ASTM A572 Gr. 50, EN 10025-4 S460 |

OD/Width 300-1200mm, WT 15-50mm |

All Regions |

|

Bridge Bracing/Cross-Frames |

ASTM A36, JIS G3106 SM490 |

Square/rectangular 100-300mm, WT 6-15mm |

West Asia, Africa |

|

Long-Span Trusses/Arches |

ASTM A514, EN 10025-4 S460 |

Round OD 200-800mm, WT 10-30mm |

Middle East, Southeast Asia |

|

Composite Floor Frames |

ASTM A709 Gr. 50W, ASTM A588 |

Rectangular 150-400mm, WT 8-20mm |

Southeast Asia, Middle East |

|

Railway Bridge Support Tubes |

ASTM A992, JIS G3106 SM570 |

Round OD 250-600mm, WT 12-25mm |

Africa, Southeast Asia |

|

Region |

Mandatory Documents |

Our Support (as construction steel pipe supplier) |

|

Middle East (GCC) |

SASO Certificate, AASHTO Compliance, Certificate of Origin |

Assist with SASO application and document verification |

|

West Asia (Iran/Iraq) |

ISIRI Certificate, Bilingual Test Reports, Import License |

Provide Persian/English documents for smooth clearance |

|

Africa (Nigeria/Kenya) |

SONCAP Certificate, Form M (Nigeria), MTC & Weld Reports |

Support SONCAP registration and product testing |

|

Southeast Asia (Indonesia/Thailand) |

SNI/TIS Certificate, Customs Declaration, Third-Party Inspection Reports |

Coordinate with local agents for regional compliance |

RFQ Question: Do your bridge steel tubes resist coastal salt spray for long-span highway bridges?

Answer: Yes, our ASTM A709 Gr. 50W weathering steel tubes develop a protective patina, resisting salt spray and corrosion. They meet AASHTO standards and include corrosion test reports for project approval.

RFQ Question: Need high-strength tubes for railway bridge piers in tropical regions—what grade do you recommend?

Answer: We recommend ASTM A572 Gr. 50 high-strength tubes, resistant to tropical humidity and heavy railway loads. They offer excellent load-bearing capacity and comply with regional structural standards.

RFQ Question: Are your square bridge tubes suitable for seismic-prone regions with temperature fluctuations?

Answer: Yes, our EN 10025-4 S460 square tubes offer superior ductility and stability for seismic zones. They adapt to extreme temperature changes and meet EN 1090 fabrication standards.

RFQ Question: Can you supply custom-profile tubes for rural bridge trusses (low maintenance)?

Answer: Our ASTM A588 weathering steel tubes are ideal for rural bridges—they require minimal maintenance and resist tropical rains and desert erosion. Custom profiles (round/square) are available to match design needs.

RFQ Question: What grade is best for bridge bracing tubes in desert regions (extreme heat)?

Answer: ASTM A36 carbon steel tubes withstand 55°C+ desert heat and wind stresses. They’re lightweight yet rigid, suitable for bracing systems, and comply with SASO regional standards.