|

Item |

Details |

|

Product Name |

Pipe Reducers (Concentric Reducer, Eccentric Reducer) |

|

Types |

Concentric Reducer (centers aligned), Eccentric Reducer (centers offset) |

|

Size Range |

½" to 48" (DN15 to DN1200); custom larger sizes for industrial applications |

|

Materials & Grades |

- Carbon Steel: ASTM A234 WPB- Stainless Steel: 304/316L- Alloy Steel: ASTM A234 WP11/WP22- Duplex Steel: UNS S31803 |

|

Pressure Rating |

Up to 9000 PSI (varies by material and size) |

|

Connection Types |

Flanged, threaded, butt-welded |

|

Key Dimensions (Example for Carbon Steel Reducers) |

- Concentric 2"×1.5" (DN50×DN40): Length 3", Weight 0.94 lbs (Standard)- Eccentric 4"×3" (DN100×DN80): Length 4", Weight 3.3 lbs (Standard)- Concentric 10"×8" (DN250×DN200): Length 7", Weight 22.1 lbs (Standard) |

|

Weight Variants |

Standard and Extra Strong (e.g., Extra Strong 2"×1.5" reducer: Weight 1.1 lbs) |

1. Raw Material Preparation:

Selection of high-quality carbon/stainless/alloy/duplex steel based on application requirements and material grades.

2. Forming:

Hot forging or cold forming to shape the steel into concentric/eccentric configurations, ensuring gradual diameter transition for smooth flow.

3. Machining:

Precision machining of both ends to match pipe diameters and connection standards, guaranteeing tight, leak-proof fits.

4. Heat Treatment:

Annealing or quenching to enhance material strength, toughness, and corrosion resistance—critical for alloy and duplex steel variants.

5. Surface Treatment:

Carbon Steel: Painting, galvanizing, or anti-corrosion coating to withstand harsh outdoor/industrial environments.

Stainless Steel/Duplex Steel: Pickling and passivation to preserve corrosion resistance and surface integrity.

6. Quality Inspection:

Dimensional checks, hydrostatic pressure testing, and non-destructive testing (NDT) to verify flow efficiency, structural integrity, and leak-proof performance.

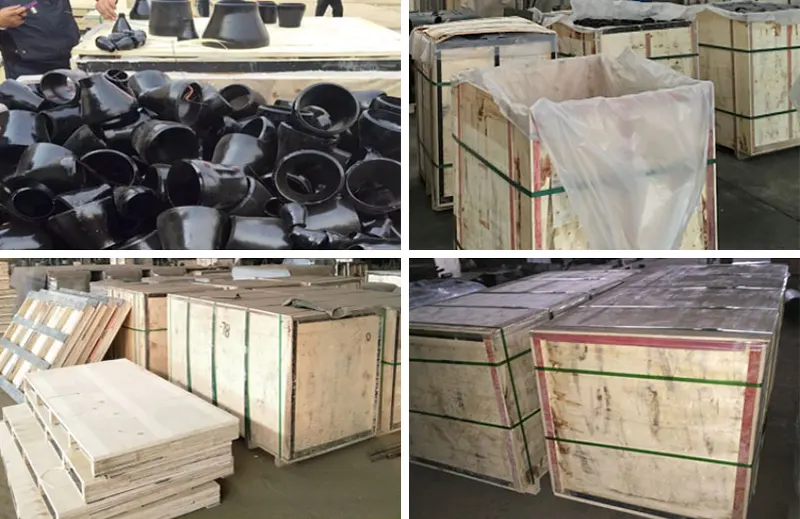

7. Packaging:

Preparation for global shipping with protective materials to prevent damage.

Superior Flow Efficiency:

Gradual diameter change minimizes pressure drop and turbulence, optimizing fluid dynamics in piping systems.

High Strength & Durability:

Steel construction withstands high pressure (up to 9000 PSI) and extreme temperatures, suitable for demanding industrial settings.

Corrosion Resistance:

Stainless steel/duplex steel variants resist humidity, salt spray, and chemical erosion; coated carbon steel adapts to harsh outdoor conditions.

Leak-Proof Connections:

Seamless/welded designs comply with ASME B16.9/ANSI B16.11, eliminating fluid leakage in critical systems.

Versatile Compatibility:

Works with various pipe materials and connection types (flanged/threaded/butt-weld), adapting to diverse project needs.

Climate Adaptability:

Performs reliably in extreme temperatures (desert heat, high-temperature industrial processes) and humid/tropical conditions.

Functional Diversity:

Eccentric reducers prevent air pockets in gravity flow systems; concentric reducers ensure uniform flow distribution.

Our Pipe Reducers comply with international and regional standards for global project approval:

|

Application |

Recommended Reducer Type |

Key Specifications |

Target Region |

|

Oil&Gas Pipelines |

Carbon Steel (ASTM A234 WPB) Concentric Reducer |

Size 4"-24", Butt-weld, Up to 9000 PSI |

Middle East, South Asia |

|

Chemical Processing Corrosive Fluids |

Stainless Steel (316L) Concentric Reducer |

Size ½"-12", Threaded/Butt-weld, Corrosion-resistant |

All Regions |

|

Water Treatment Gravity Flow Systems |

Carbon Steel Galvanized Eccentric Reducer |

Size 2"-18", Flanged, Air pocket prevention |

Africa, Southeast Asia |

|

Power Plant High-Temperature Steam Lines |

Alloy Steel (ASTM A234 WP22) Concentric Reducer |

Size 2"-16", Butt-weld, High-temperature resistance |

Middle East, South America |

|

Offshore Oil&Gas Systems |

Duplex Steel (UNS S31803) Eccentric Reducer |

Size 6"-24", Butt-weld, Superior corrosion resistance |

All Regions |

|

Region |

Mandatory Documents |

Our Support |

|

Middle East (GCC) |

SASO Certificate, Certificate of Origin, MTC |

Assist with SASO application (3-5 working days) |

|

Africa (Nigeria/Kenya) |

SONCAP Certificate, Form M (Nigeria), CoO |

Support SONCAP registration and product testing |

|

Southeast Asia (Indonesia/Thailand) |

SNI/TIS Certificate, Customs Declaration, Pressure Test Reports |

Coordinate with local agents for clearance |

|

South America (Brazil/Argentina) |

Certificate of Conformity, Import License, MTC |

Provide Spanish/Portuguese bilingual documents |

|

South Asia (India/Pakistan) |

BIS Certificate (India), Import Permit, CoO |

Assist with regional certification processes |

RFQ Question: Do your stainless steel reducers resist coastal salt spray for chemical fluid systems?

Answer: Yes, our 316L stainless steel reducers offer superior saltwater corrosion resistance, ideal for coastal chemical systems.

RFQ Question: Need eccentric carbon steel reducers for water treatment—can they withstand tropical rains?

Answer: Our galvanized carbon steel eccentric reducers resist tropical humidity and rains, preventing air pockets in gravity flow systems.

RFQ Question: Can you supply custom-size alloy steel reducers for high-temperature power plant use?

Answer: Yes, we offer custom-size alloy steel reducers (ASTM A234 WP22) designed for high-temperature steam lines.

RFQ Question: What’s the warranty for carbon steel reducers used in oil&gas pipelines?

Answer: Our carbon steel reducers come with a 3-year warranty against manufacturing defects, ideal for oil&gas pipeline use.

RFQ Question: Can your concentric reducers handle high pressure in chemical processing?

Answer: Our stainless steel (316L) concentric reducers are rated for high pressure (up to 9000 PSI) in chemical processing.