|

Item |

Details |

|

Product Name |

Steel Sheet Pile |

|

Profiles |

U-section, Z-section, straight web section (with interlocking edges) |

|

Key Dimensions |

- Width: 400mm to 800mm (standard sections)- Depth (Height): 75mm to 500mm- Thickness: 6mm to 24mm- Length: 6m to 24m; custom lengths available |

|

Material Grades |

- Carbon Steel: ASTM A572 Gr. 50/55, ASTM A328, EN 10248 S270GP/S355GP- High-Strength/Marine Grade: ASTM A690, JIS G 3114 SMA400/500- Weathering Steel: ASTM A588 |

|

Manufacturing Methods |

Hot-rolling, cold-forming; welded built-up/composite sections (SAW) |

|

Mechanical Properties |

- Yield Strength: 275MPa (EN 10248 S270GP) to 460MPa (ASTM A690)- Tensile Strength: 430MPa (EN 10248 S270GP) to 655MPa (ASTM A690)- Interlock Tightness: Watertight seal for water control applications |

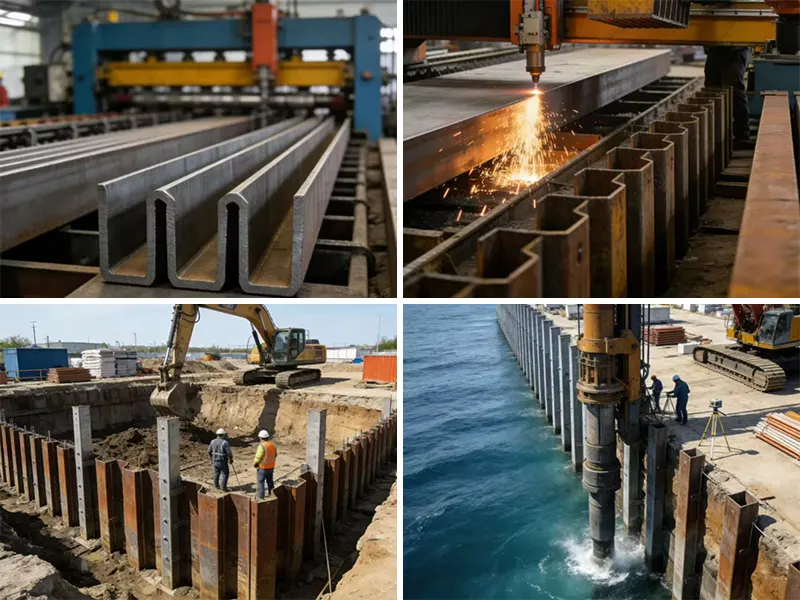

1. Steel Preparation:

Conditioning and edge preparation of high-quality steel plates/coils to ensure precision for forming.

2. Forming:

Hot-rolling or cold-forming into U, Z, or straight web profiles with engineered interlocking edges—critical for watertight performance.

3. Welding (if applicable):

Submerged Arc Welding (SAW) for built-up/composite sections, ensuring strength and continuity.

4. Straightening & Cutting:

Precision leveling to maintain dimensional accuracy, followed by cutting to specified lengths.

5. Surface Treatment:

Shot blasting and application of protective coatings (primers, epoxy) to resist corrosion from soil, water, and regional climates.

6. Testing & Inspection:

Dimensional verification, tensile/bending tests, Charpy impact tests, and non-destructive weld testing (if welded).

7. Finishing:

Quality checks for interlock functionality, ensuring seamless installation and watertight sealing.

Watertight Integrity:

Interlocking edges create continuous barriers, ideal for cofferdams, flood defense, and marine structures.

Superior Strength & Load-Bearing:

High-strength steel grades withstand earth pressure, water loads, and dynamic stresses in construction.

Corrosion Resistance:

Marine-grade (ASTM A690) and weathering steel (ASTM A588) variants resist saltwater, tropical humidity, and desert erosion.

Easy Installation:

Lightweight yet durable, compatible with driving, vibratory, or hydraulic installation methods.

Climate Adaptability:

Performs reliably in extreme temperatures (-10°C to 55°C), flood-prone areas, and coastal environments.

Cost-Effective Versatility:

Suitable for permanent/temporary projects (retaining walls, land reclamation) across target regions.

Our Steel Sheet Pile complies with global and regional construction standards:

|

Application |

Recommended Material Grade |

Key Specifications |

Target Region |

|

Marine Port/Bulkheads |

ASTM A690, JIS G 3114 SMA500 |

U/Z-section, 6-24mm thickness, corrosion-resistant |

Southeast Asia, Middle East |

|

Flood Defense/Levees |

ASTM A572 Gr. 55, EN 10248 S355GP |

Straight web/U-section, 8-16mm thickness, watertight |

Africa, West Asia |

|

Retaining Walls (Highways/Basements) |

ASTM A328, EN 10248 S270GP |

U-section, 6-12mm thickness, easy installation |

All Regions |

|

Cofferdams (Bridge Piers) |

ASTM A690, ASTM A588 |

Z-section, 12-24mm thickness, high-strength |

All Regions |

|

Land Reclamation |

JIS G 3114 SMA400, EN 10248 S355GP |

U/Z-section, 10-20mm thickness, durable |

Southeast Asia, Africa |

|

Region |

Mandatory Documents |

Our Support |

|

Middle East (GCC) |

SASO Certificate, Mill Test Certificate 3.2, Certificate of Origin |

Assist with SASO application (3-5 working days) |

|

West Asia (Iran/Iraq) |

ISIRI Certificate, Bilingual Test Reports, Import License |

Provide Persian/English documents for clearance |

|

Africa (Nigeria/Kenya) |

SONCAP Certificate, Form M (Nigeria), CoO & Corrosion Reports |

Support SONCAP registration and product testing |

|

Southeast Asia (Indonesia/Thailand) |

SNI/TIS Certificate, Customs Declaration, Interlock Test Reports |

Coordinate with local agents for smooth clearance |

RFQ Question: Do your steel sheet piles resist saltwater corrosion for coastal port construction?

Answer: Yes, our ASTM A690 marine-grade sheet piles resist saltwater corrosion. They feature watertight interlocks, meet EN 10248 standards.

RFQ Question: Need watertight piles for flood defense in tropical rain-prone regions—what grade do you recommend?

Answer: We recommend ASTM A572 Gr. 55 sheet piles, designed for watertight flood barriers. They resist tropical humidity, are easy to instal.

RFQ Question: Are your Z-section sheet piles suitable for cofferdams in temperature-fluctuating regions?

Answer: Yes, our EN 10248 S355GP Z-section piles adapt to -10°C to 45°C fluctuations. They offer high strength and watertight seals.

RFQ Question: Can you supply custom-length steel sheet piles for rural land reclamation projects?

Answer: Our JIS G 3114 SMA400 piles are available in custom lengths (6m-24m) for land reclamation. They’re durable, corrosion-resistant with custom profile options.

RFQ Question: What grade is best for retaining walls in desert regions (sand erosion)

Answer: ASTM A588 weathering steel sheet piles withstand desert sand erosion and heat. They develop a protective patina, require low maintenance.

RFQ Question: Do your sheet piles support quick installation for temporary construction cofferdams?

Answer: Yes, our lightweight EN 10248 S270GP U-section piles enable quick vibratory installation.