We specialize in providing customized steel products tailored to meet the unique requirements of our clients. Whether you have detailed designs, specific dimensions, or unique material specifications, we have the expertise and advanced manufacturing capabilities to bring your ideas to life. Here’s how we ensure your custom steel products are delivered to the highest standards:

1. Customization Process

Design Review: Our engineering team works closely with you to review your designs, ensuring they are feasible and optimized for performance.

Material Selection: We offer a wide range of steel grades and finishes to match your application needs, including carbon steel, stainless steel, alloy steel, and more.

Precision Manufacturing: Using state-of-the-art equipment such as CNC machines, laser cutters, and precision welding tools, we produce components with exceptional accuracy.

Quality Assurance: Every custom product undergoes rigorous testing and inspection to ensure it meets industry standards and your specifications.

2. Types of Custom Steel Products

Structural Components: Beams, columns, and frames tailored for construction projects.

Machinery Parts: Custom gears, shafts, and fittings for industrial equipment.

Pipes and Tubes: Custom-sized and shaped pipes for oil and gas, water supply, and HVAC systems.

Decorative Elements: Unique steel designs for architectural and artistic applications.

Specialized Fabrications: Complex assemblies and prototypes for specific industrial needs.

Shotblasting is a method used to clean, strengthen (peen) or polish metal. There are two technologies used: wheelblasting or airblasting.

We can cut tubes to the exact length required by client to meet for different size of projects.

Beveling is the process in which we form an angle between the edge of a pipe and a plane perpendicular to the surface to a certain degree, most commonly used to prepare the ends of pipes for welding.

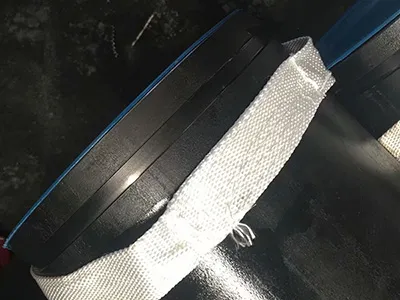

We can provide both cut grooving and roll grooving. Cut and roll grooving can be done in any style according to industry standards

Threaded pipes can provide an effective seal for pipes transporting liquids, gases, steam, and hydraulic fluid. We thread any length of pipe in diameters ranging from 1/8” to 20”. Tapers available are NPT*, NPS*, 3/16” Peerless, and 8 round taper.

Using a high power density laser beam to irradiate the material to be processed, the material is quickly heated to vaporization temperature and evaporates to form a hole. It is a high quality, fast, and accurate way of punching holes.

Customizing steel fittings and adaptable processing according to customer's project size requirements and drawings.