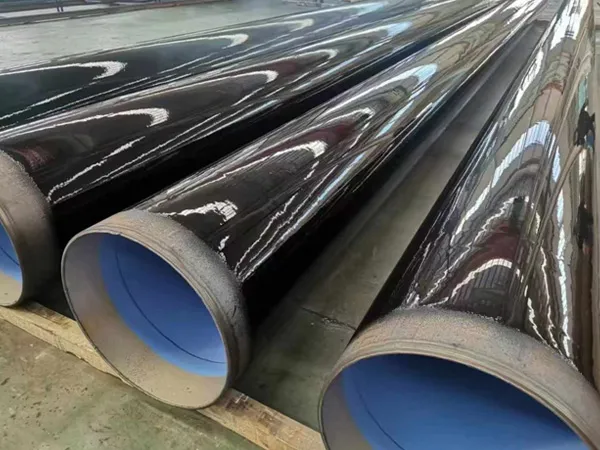

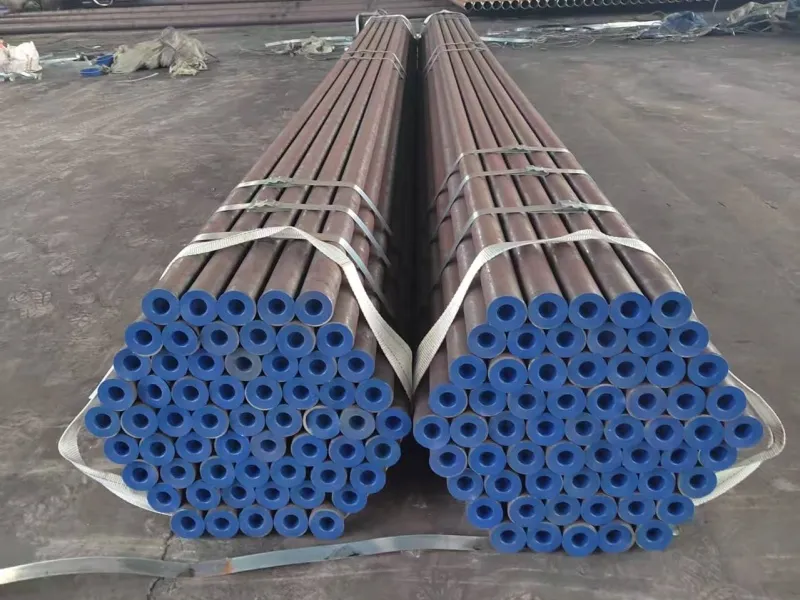

We successfully delivered a high-corrosion-resistant seawater intake system for a 300,000-ton/day desalination plant in a challenging marine environment. The project involved the supply of LSAW pipes (OD711mm & OD508mm, thickness 16-18mm) constructed from ASTM A252-grade steel with Hardtop XP series anti-corrosion coating, ensuring long-term durability against saltwater corrosion.

Our End-to-End Project Execution (4-Month Timeline)

1. Project Initiation & Engineering (Week 1-2)

Conducted corrosion resistance studies with third-party labs to validate Hardtop XP coating suitability.

Customized pipe specifications to meet ASTM A252 requirements for high-stress marine applications.

Collaborated with the client’s engineering team to finalize welding procedures (WPS/PQR).

2. Manufacturing & Coating (Week 3-8)

Pipe Production:

Utilized JCOE forming technology for high-precision LSAW pipes.

Implemented automated submerged arc welding (SAW) for consistent seam quality.

Corrosion Protection:

Applied Hardtop XP coating via robotic spraying for uniform thickness (400-500µm).

Conducted holiday detection (30kV) to ensure zero coating defects.

3. Rigorous Testing (Week 9-10)

Mechanical Tests: Tensile, hardness, and Charpy impact tests per ASTM A370.

Pressure Testing: Hydrostatic tested at 1.5x working pressure (15 bar).

Non-Destructive Testing (NDT):

Ultrasonic Testing (UT) for weld integrity.

Radiographic Testing (RT) on 10% of welds (per client request).

4. Logistics & On-Time Delivery (Week 11-16)

Shipping: Arranged bulk cargo.